The Function of Foam Control in Enhancing Product Top Quality and Efficiency

Foam control is an often-overlooked yet crucial element in the search of item top quality and functional effectiveness throughout varied industries. This conversation will check out the complex influence of foam on both product honesty and production procedures, elevating essential inquiries about the strategies that can be used to enhance foam control.

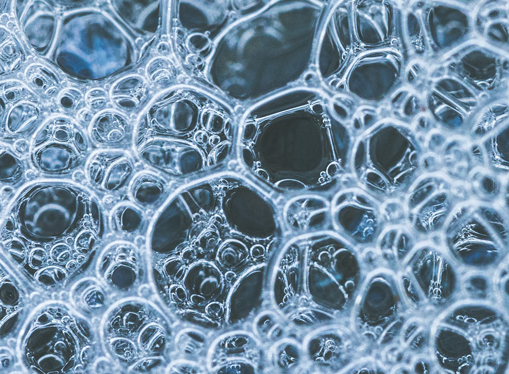

Understanding Foam Formation

Foam formation is a complicated sensation that can substantially influence item top quality and operational effectiveness across different markets. It happens when gas bubbles come to be trapped in a liquid, leading to the creation of a frothy structure. Numerous elements contribute to this process, including the physical and chemical properties of the fluid, the presence of surfactants, and the problems under which mixing happens. Understanding these variables is crucial for handling foam properly.

The liquid's viscosity and surface area tension play critical roles in foam security. Surfactants, for instance, can decrease surface tension, promoting bubble formation yet likewise boosting foam security, which can be troublesome in certain applications. Moreover, mechanical agitation, temperature variations, and the existence of contaminations can worsen foam generation, making it vital to keep track of these facets throughout production processes.

Industries such as food and beverage, pharmaceuticals, and chemical production have to be particularly watchful relating to foam control. By grasping the underlying devices of foam development, companies can apply targeted strategies to alleviate its impacts, consequently preserving operational efficiency and ensuring consistent product performance.

Effect On Product Quality

The visibility of foam can significantly jeopardize item top quality throughout various industries. In producing procedures such as food and beverage, pharmaceuticals, and cosmetics, excessive foam can result in inconsistent item formulations. In food production, foam might trap air, influencing texture and taste, which can inevitably change customer assumption and contentment.

Moreover, foam can hinder the uniformity of paints and finishings, resulting in issues like bubbles and unequal finishes. In pharmaceutical applications, foam can hinder the precise dosing of liquid drugs, potentially influencing therapeutic efficiency and client security. These top quality problems not only decrease the end product's allure however can also lead to pricey recalls and damages to brand track record.

Furthermore, the existence of foam can complicate quality assurance steps, making it challenging to accomplish consistent outcomes and specific measurements. Effective foam control not only alleviates these threats however also improves overall product top quality by ensuring that solutions satisfy rigid industry criteria. By purchasing foam control strategies, business can protect their products, improve consumer satisfaction, and keep an one-upmanship in the industry.

Operational Obstacles From Foam

Effective procedures in different sectors can be severely interfered with by the presence of foam, which presents numerous obstacles throughout production processes. Foam can impede blending and response times, restraining the effectiveness of chemical procedures. In industries such as food and drink, foam development can result in incorrect fill levels, leading to product waste and inconsistencies in packaging.

In settings where health is paramount, such as pharmaceuticals and food processing, foam can make complex cleaning protocols, creating surprise tanks for pollutants. This not just increases quality problems yet additionally can bring about conformity issues with regulatory requirements.

Moreover, the psychological influence on operators can not be overlooked; excessive foam can create a chaotic work atmosphere, bring about reduced spirits and efficiency. In recap, addressing the functional difficulties postured by foam is vital to maintaining efficiency and item quality in different industries.

Strategies for Effective Foam Control

How can industries effectively mitigate the difficulties postured by foam? Efficient foam control methods are important for boosting product quality and operational performance.

Along with chemical remedies, procedure optimization plays an important duty in foam monitoring. Industries can evaluate and change parameters such as blending rate, temperature, and stress to decrease foam generation. Executing equipment adjustments, like mounting foam-breaking tools or adjusting tank layout, can further help in reducing foam degrees.

Normal monitoring and evaluation of foam actions within manufacturing procedures are additionally important. Utilizing sophisticated sensors and analytics can offer real-time data, permitting timely interventions and changes. Staff training is just as important; guaranteeing that employees are knowledgeable concerning foam dynamics and control techniques can result in proactive foam administration.

Situation Researches and Sector Applications

While numerous markets encounter distinct difficulties associated with foam control, instance research studies expose that tailored techniques can dramatically improve both product high quality and operational effectiveness. In the pharmaceutical industry, as an example, a leading maker implemented a custom foam why not find out more control technique that reduced foam development during fermentation procedures. This development not only boosted yield by 15% however also reduced contamination dangers, guaranteeing higher product integrity.

Likewise, in the food and drink industry, a major milk producer faced excessive foam during pasteurization - Foam Control. By presenting a specialized antifoam agent, they reduced processing time by 20%, which straight equated to boosted throughput and minimized power intake. The application of foam control determines ensured regular product appearance and taste, reinforcing brand name commitment

In the chemical manufacturing field, a case research study highlighted the effective application of foam control in wastewater therapy procedures. The implementation of a real-time tracking system permitted operators to adjust antifoam dose dynamically, causing a 30% decrease in chemical usage and boosted effluent high quality.

These instance studies highlight the diverse applications of foam control throughout sectors, stressing its essential duty in enhancing product high quality and operational efficiency.

Conclusion

In conclusion, effective foam control is indispensable to improving product quality and functional performance throughout different markets. Eventually, focusing on foam control adds to improved efficiency, guarding brand name credibility, and increasing customer contentment, highlighting its value in quality guarantee within manufacturing processes.

Foam control is an often-overlooked yet important component in the search of product top quality and operational performance throughout diverse markets. Personnel training is just as crucial; guaranteeing that workers are educated about foam dynamics and control strategies can lead to positive foam management.

While many sectors face one-of-a-kind difficulties connected to foam control, situation research studies expose that customized strategies can significantly improve both product high quality and functional performance (Foam Control). In the pharmaceutical industry, for instance, a leading supplier applied a customized foam control technique that reduced foam formation during fermentation processes.In conclusion, reliable foam control is integral to improving item high quality and operational performance across different sectors